|

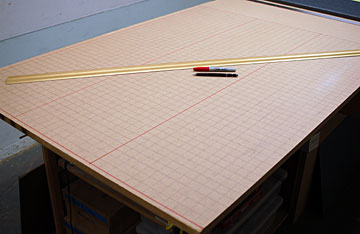

I decided to make each of my boards 12" x 48" using 3/4" MDF.

This piece allowed me to make three boards in addition to the two I had

already made. Draw a grid in whatever increments you think will

work best. I decided on a 1" x 1" grid which meant drilling 11 x 47

(517) holes in each board. This is one of those times when having a

light drill is a blessing. Much after the fact it occurred to me that

rather than drawing a grid I could have just laid a piece of pegboard over

the MDF and used it as a drill guide. |

|

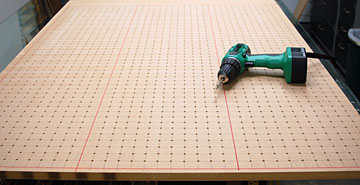

The

extra hands are

flexible so I wasn't worried about making the holes exactly

perpendicular which would have taken far longer. A good eyeball is

all that is necessary. The

extra hands are

flexible so I wasn't worried about making the holes exactly

perpendicular which would have taken far longer. A good eyeball is

all that is necessary.

Drilling all

these holes took about 2-1/2 hours. I don't regret doing it, but no, I never want to do

this again.

I used a wheel collar as a depth-stop on the drill

bit to prevent drilling all the way through the board. The holes

are drilled approximately 5/8" deep. (I'll bet 90% of everybody

just stopped reading this page) |

|

The boards were cut apart using a circular saw guided by

a

straight edge clamped to the boards. I used a 1/4" rounding

bit in my router to clean up the edges. |

|

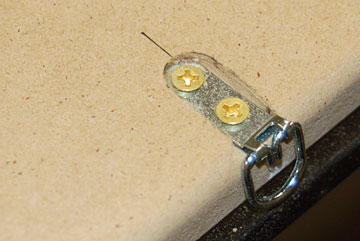

A mirror hanger is added to the back of each board so I

can hang it from the wall out of the way.

I used my Dremel router to inset the hanger slightly. |

|

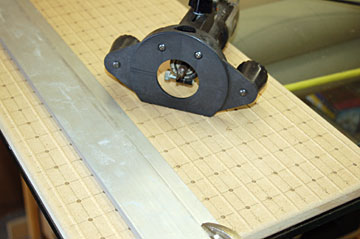

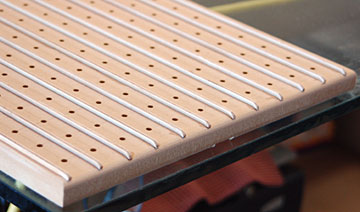

This step is probably optional for most builders. I

added strips to the board to support the

fixtures I make while painting them. Most of the model parts I

paint will be held by extra hands so the support strips won't be

necessary. I used my

Dremel tool with a router base and 1/8" straight routing bit to cut

full length grooves approximately 1/16" deep to receive the support

strips. |

|

I cut 1/8"

plywood into 3/16" wide strips using my

Microlux Table saw. I would rather have used inexpensive

pre-cut hardwood but I didn't have any on hand. The hardwood I do

have was fairly expensive and I didn't feel this was a good use for it.

The strips are glued into the routed grooves using thin

CA. I used a long

sanding block to level the strips and rounded over the ends so they

wouldn't cut up my hands while moving the boards around. |

|

Finally a good coat of paint was sprayed all over to seal

the boards. MDF is easily ruined when it gets wet. I applied

a couple heavy coats of car wax to help prevent overspray from sticking

when painting models. |

|

An eyebolt was added to each board so I can hang my spray

gun to it. I have a clamp-on style airbrush holder that will be

clamped to whatever board is in use at the time. The eyebolt

was cut off using my Dremel tool. |

|

The

spray gun placed on the hook. |

|

Vertical presses for my

magnetic building system are slid

onto a piece of music wire held by extra hands. Wheel chocks

have a screw threaded into them that is held by the extra hands. |

|

Shown here are four sets of fixtures and miscellaneous

other pieces that were lacquered and are now drying in the sun and not

filling my shop with fumes. |

|

These pieces have a bolt threaded in and were then soaked

in Danish Oil. They are clipped to extra hands to dry in the sun. |

![]()