|

Before the wing can be mounted it must to be

shaped as closely as possible to its finished shape. A razor plane is

used to rough-in the

leading edge. A long sanding block finishes the job. Do

not make the mistake of giving the leading edge any shape that pleases

you. The leading edge shape should closely match the plan.

In the worst case a poorly shaped leading edge can lead to devastating

stall characteristics.

It is best to cut out a cardstock

template

to place over the leading edge as you shape it. |

|

This shape very closely matches that of the

airfoil as designed. Notice that the

sheeting and leading edge are

still over-length. The excess must be trimmed and sanded off before proceeding. |

|

Most plans indicate that the wing tips should be glued on

prior to mounting the wing. In theory that is a good idea, but I

like to mount the wing before the tips are in place.

The shape of the tips is usually open to

interpretation and one tip may or may not exactly match the other.

If the rear, outboard corner of the tip is rounded then there is no set

point to measure from.

Therefore I measure to the last rib.

Wing tips that vary slightly in shape will not

affect flight or

trim characteristics noticeably. |

|

It is important that the tip ribs are

related identically.

Some wings may have ribs that are not parallel to the centerline of the

aircraft. That is OK, but you will need some type of triangle

template to ensure both ribs are the same.

In this case, as is most common, the tips

are parallel to the aircraft centerline. I use my old, rusty

framing square to ensure the tips are sanded square to the wing. |

|

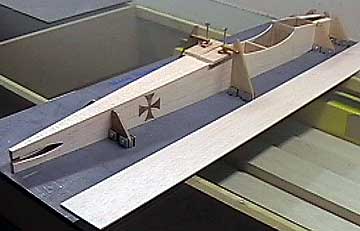

The fuselage must be set on a flat surface

large enough so the wing does not over-hang any edge. Use

weights or pin the fuselage to your building board. The important

thing is to ensure that the fuselage can't move. |

|

Center the wing on the fuselage. I

usually measure each wing tip from the opposite fuselage side because it

provides a convenient point to hold the tape measure. You should be able to get

all matching distances within 1/16" without difficulty. |

|

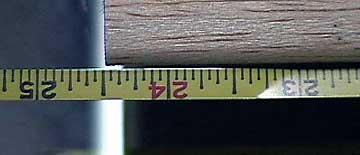

The measurement to the left wing tip. |

|

The measurement to the right wing tip.

Both tips are very slightly under 24-1/2" from the opposite fuselage

side. |

|

Next, measure from the center of the tail-post to each wing tip. If the distance is not the same to each wing

tip, then you will have to adjust it and then go back and re-center the

wing. To clarify — any

time you move the wing you must check all measurements again.

It can get tedious, but if you built accurately in the first place then

it shouldn't take more than two or three iterations to get the wing square. |

|

The measurement to the right wing tip. |

|

The measurement to the left wing tip.

Both measurements are 34-5/8". |

|

Lock the wing in place on the fuselage when

you are satisfied that the wing is square to it. You can use pins,

weight, clamps or anything that will prevent it from moving.

Use a soft pencil or fine-point marker to

make alignment marks on the wing and fuselage. You should make a

minimum of three marks.

At this point you should check the wing

incidence. If it is correct then you can move along to the next

step. If not then make adjustments to the wing saddle until the

incidence is correct.

Do not continue until you have done this

because it is easiest to adjust before the leading edge

dowels are in

place. |

|

Check the height of each wing tip. Make adjustments to the

wing saddle

as necessary.

Sand the high saddle or shim the low saddle depending on

whether the wing needs to be raised or lowered. With each

adjustment you should also check the incidence again. Because you have to remove the wing, you will need to go back to the

beginning and re-measure everything. The alignment

marks you made should position the wing very close when it is replaced,

but check anyway.

Do not drill for wing dowels or hold-down

bolts until you are absolutely satisfied the wing is mounted as straight

as it can be. If you do not take your time with this step your

plane will never trim properly.

|

![]()