How

to Align Cabane Struts on Biplanes and Parasol Aircraft

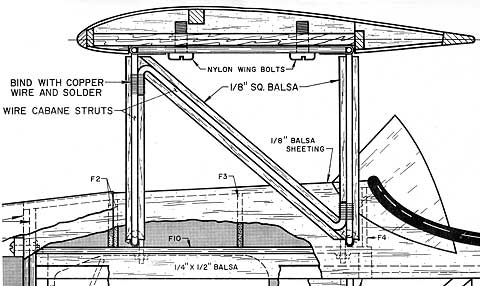

My Sig Smith Miniplane, like most biplanes, uses cabane struts to mount the wing.

The core of the mount is a plywood plate in the fuselage (F10). The

plywood mounts to 1/4" x 1/2 balsa stock that must be perfectly aligned on both

fuselage sides. If these are wrong then everything that follows will also

be wrong.

There are two brass tubes that are J-bolted and epoxied to the plywood plate.

These must also be perfectly aligned. Into these tubes are epoxied the

four cabane pieces. Each of the cabane pieces is made from 1/8" music wire

and is bent into a Z shape more or less. The arrangement makes a

parallelogram that may or may not be straight, true and level by the time it is

finished.

A diagonal piece of music wire is wire wrapped

and soldered to the cabanes. When this is complete two pieces of brass

plate are wrapped around the top of the cabanes and soldered in place.

Between the brass pieces is another piece of plywood that is epoxied in place.

Assuming the plate and tubes are correct in the fuselage, it is still

possible to have one set of cabanes rotate further forward or aft of the other.

This will result in the wing being lower on that side of the aircraft. In

theory, the diagonal piece will ensure that the cabanes on both sides are

identical. It does not work out that way in practice unless careful

measurements are taken.

Image from Sig Smith Miniplane plans

First I tried to block the fuselage level and perpendicular to the

building surface. That meant dropping a centerline from the fuselage

to the building surface as a reference line. From this line I would have

to go back up to the cabanes to ensure they were aligned properly to the

fuselage and each other.

I messed around with this for about an hour before coming to the conclusion that

I just couldn't do it with any degree of accuracy. Eye-balling it

would have given me close to the same result.

Then I had a brainstorm. I knew that the firewall was perpendicular to the fuselage centerline in both top and side view

so it

could be used as a reference. Here's how I did it:

|

![]()